Prestressed Masonry -Methods of Prestressing, Advantages and Applications

Prestressed masonry makes the masonry structures strong in tension. Advantages and applications of prestressed masonry and their methods of prestressing is discussed.

Prestressed Masonry – Advantages and Applications, Methods of Prestressing

Generally, masonry is substantially very strong in compression however it is considerably weak in tension and this is the cause of limitation of masonry utilization in structural member which are subjected to tension force.

Moreover, the restriction on the use of masonry can be tackled by introducing either reinforced or prestressed bars.

Prestressed masonry may be obtained by providing compressions in advance at a required degree to act opposite to the tension that the masonry subjected to under service loads.

In this article the prestressing masonry advantages, methods of prestressing, and its applications will be discussed in the following sections.

Fig.1: Prestressed Masonry Model Constructed from Fly Ash Brick

Fig.2: Use of Prestressing for Concrete Block Masonry Wall

Advantages of Prestressed Masonry compared with Reinforced Masonry

Effective Application of Materials

As it is known, in reinforced masonry, the area located above neutral axis is working and effective against the applied moment. Moreover, to control cracks and hold them at an acceptable range, low strain in steel reinforcement needs to be maintained and this lead to prevent the utilization of ultimate capacity of high tensile steel bars. However, the entire section in prestressed masonry is effective and works against the applied moment as illustrated in Figure-3.

Fig.3: In Prestressed Masonry the Applied Moment is Resisted by the Entire Cross Sectional Area

Increased Shear Strength of Prestressed Masonry

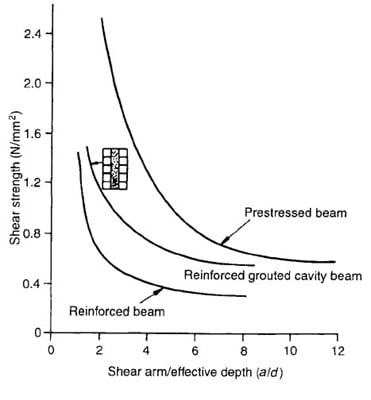

The shear strength that is increased due to prestressed tendons is greater than that of reinforcement bars. This can be further clarified by observing Figure-4 that shows the shear strength of prestressed and reinforced brickwork beams in relation to the shear arm to effective depth ratio.

It can be seen that, the shear strength of reinforced grouted brickwork cavity beam and reinforced brickwork beam is considerably smaller than the shear strength of completely prestressed brickwork beam with bonded tendons.

One might argue that this statement is related to brickwork beam however it is applicable to other kinds of masonry flexural elements.

Fig.4: Shear Strength of Various Types of Brickwork Beams of Similar Cross Sections

Enhanced Service and Overload Behavior

It is possible to control both cracks and deflection in prestressed masonry provided suitable degree of prestressing is applied. Moreover, under service load condition, complete prevention of cracking and deflection is likely to be achieved when the element is prestressed completely. Added to that, cracks due to overloading are almost eliminated.

High fatigue resistance: prestressed masonry provides large resistance against fatigue because the strain in prestressed steel is considerably small when applied loads are changed.

Prestressed Masonry Prestressing Methods

There two techniques which are used for prestressing and they are similar to those of prestressed concrete:

Pre-Tensioning Technique

Tendons are tensioned between external anchorages, to a specified degree. When masonry and the infill material have achieved enough strength, the tendons are carefully released.

In this process, the forces in the tendons are transferred to infill material and then transferred to the masonry though the bond between masonry and its infill material.

Post-Tensioning Technique

After the masonry achieved enough strength, tendons are tensioned by applying suitable means such as jacking against masonry. Forces in tendons are transferred to masonry by either external bearing plate or anchorage blocks that is set in concrete.

Moreover, there are cases in which the force in the tendon is transferred to the masonry through threaded nuts bearing against steel washers on a solid steel plate which distribute the exerted force.

Tendons can be bonded or unbonded and it is advised to protect tendons by grouting or other means to provide better durability.

This method is best suited for brick masonry and it is considerably simple and easy to employ in practice.

It is beneficial to vary prestressing force eccentricity along the length of the masonry flexural member for instance it is better to provide greatest eccentricity at the mid span of simply supported beam at which the applied moment is largest and provide zero eccentricity at the support.

Furthermore, except if specific clay brick units are formed to suit cable profile to cater the applied bending at various sections, clay brick application might be restricted because of low level prestressing that withstand tensile stress in the wall generated by wind load, and high level of prestressing elements that carry loads due to bending for example retaining walls and beams are of small to medium span.

Fig.5: Post Tensioning Prestressed Concrete Block Masonry

Applications of Prestressed Masonry

Prestressing masonry is likely to speed up the construction because not only does it need less amount of steel tendons compare with conventional masonry reinforcement but also require less grout quantity. This cost reduction may be offset partially by the cost of installation.

Various applications of prestressed masonry are provided in the following sections:

- Prestressing masonry can used to construct tilt up walls for slender wall.

- Prestressed masonry shear walls can be used in low seismic areas as it is recommended by the Unites States codes.

- Prestressed masonry is considerably appropriate for walls of one or two storeys. And it is perfect for retail buildings, warehouse, offices, gymnasium, school, and tall-wall buildings in addition to use for façade of parking structure. Numbers of prestressed masonry application are shown in Figure-6 and Figure-7.

- In addition to construct structures using prestressing masonry, prestressing is used to strengthen and repair deteriorated masonry structures as shown in Figure-8, Figure-9, and Figure-10.

Fig.6: Prestressed Masonry Building

Fig.7: Bridge in England, all Retaining Walls are Constructed using Prestressed Masonry Brickworks

Fig.8: Masonry Wall Strengthen Using Prestressing Tendons

Fig.9: Access Ports at Bottom, An Addition Port Provided at Mid Height

Fig.10: Historic Building

Figure-8 shows a structure whose walls are strengthened using prestressing. Traditional masonry strengthening includes cutting open in the wall and then installing steel and finally pouring gouts.

In contrary, this wall strengthened with much smaller number of opens and without using grouts.

Figure-10 shows a historic building that is constructed from stone. The top final members were removed because of structural issue caused by being too tall and slender. These elements were rebuilt using prestressing to secure them to the walls below.

Comments