Types of Economical Floor Systems for Reinforced Concrete Buildings

There are different types of economical floor systems (slabs) for reinforced concrete buildings that nearly satisfy all loading and span conditions. Selecting economical floor systems which can withstand design requirements is discussed.

Reinforced concrete provides wide range structural choices for numerous conditions such as residential buildings, offices and industrial buildings.

Due to the fact that floor system cost constitute major part of structural cost, therefore selection of an economical floor system would affect the overall cost of the project.

There are number of factors that influence the economy of floor systems such as building type, architectural layout, span length between columns and aesthetic features.

In this article, guidelines that lead to an economical selection of floor systems will be provided.

Types of Economical Reinforced Concrete Floor Systems for Buildings and Structures

Following are the different types of economical concrete floor systems. Their selection criteria, advantages and uses are discussed in detail.

- Flat plate slabs

- Flat slabs

- Waffle slabs

- Slabs on beam

- One way slab on beams

- One-way joist floor system

Flat Plate Slab Floor System

Flat plate systems are directly supported by columns and suitable for span of 6-8m with life load of 3-5KN/m2. This type of floor system is adopted mainly for hotels, hospitals, multifamily residential buildings.

The most outstanding advantages of flat plates include fast construction, simple and low formwork cost, flat ceiling that reduces finishing cost.

When flat plates are used in the construction of buildings, the total height of structure can be decreased which is an advantage from economical point of view.

This is because the decrease of total building height would lead to reduction in vertical runs of cladding, partition walls, mechanical systems, plumbing and many other items of construction.

Another advantage of flat plates is that it would allow the increase of storey numbers in structures of restricted height.

It should be considered that the relative stiffness and shear capacity of flat plates are low.

Fig.1: Flat Plate Slab Floor System

Flat Slab Systems for Buildings

Flat slabs are similar to flat plate apart from thickening of flat slabs around columns which are provided to improve shear capacity of this floor system.

Flat slabs are economically viable for spans range from 6 to 9m and live loads range from 4 to 7 KN/m2.

This type of floor system is suitable for the case where punching shear stress prevent the use of flat plates especially when relatively shallow slabs are intended. It should be known that thickening of floor system around columns (drop panels) increase the cost of formworks.

The thickness of flat slab is 10 percent smaller than that of flat plate for the same span length. ACI code specified the dimension of drop panels so as to take advantage of this reduced thickness.

It is claimed that the cost of formwork, concrete material placement and finishing, and steel placement are 47%, 36%, and 17%, respectively of overall floor cost for flat slabs.

Fig.2: Flat Slab Floor System

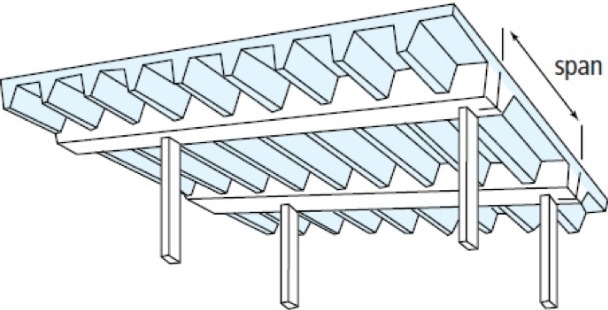

Waffle Slabs

It is consist of reinforced concrete slab and evenly distributed waffle slab in two directions. The slab around columns is solid to provide shear resistance in column area.

Waffle slabs are economically appropriate for spans of 9 to 15m and live load of 4 to 7KN/m2. The ultimate load carrying capacity of this floor system is greater than of flat slabs, but cost of its formworks is substantially high.

Fig.3: Waffle Slab

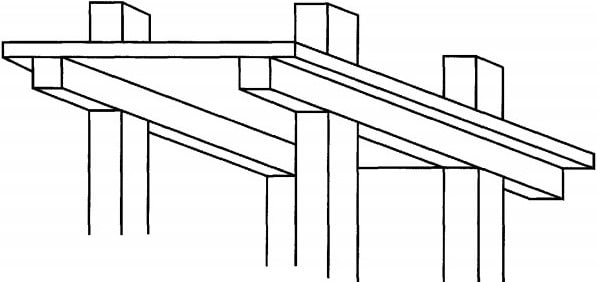

Slabs on Beams

This type of floor system is economically viable for spans ranges from 6 to 9m and live load of 3 to 6KN/m2.

The beam increases the relative stiffness of the floor system and hence the deflection is declined, but the cost of formwork is increased due to beam formwork.

Fig.4: Slabs on Beams

One-way Slab on Beams

This type of floor system is suitable for span of 3 to 6m and live load of 3 to 5KN/m2. This span range can be increased at the expense of slight increase of deflections and cost of the floor system.

Fig.5: One-Way Slab on Beams

One-Way Joist Floor System

It consists of uniformly spaced concrete ribs spanning in one direction, reinforced concrete slab constructed monolithically with ribs and beams which are spanning between columns.

On way joist floor system is economically suitable for spans of 6 to 9m and live load of 4 to 6KN/m2.

There are several advantages offered by this floor system such as it is cost effective for long spans with heavy loads, the overall depth does not require to be increased for utility installation because they can be placed between joists and pan voids reduces self-weight.

It is reported that of cost of formworks constitute about 51 percent of the total cost of the floor system.

Fig.6: One Way Joist Floor System

Comments