How to determine the Penetration Value of Bitumen -Determination for Road Construction

Penetration value test on bitumen is a measure of hardness or consistency of bituminous material. A 80/100 grade bitumen indicates that its penetration value lies between 80 & 100.

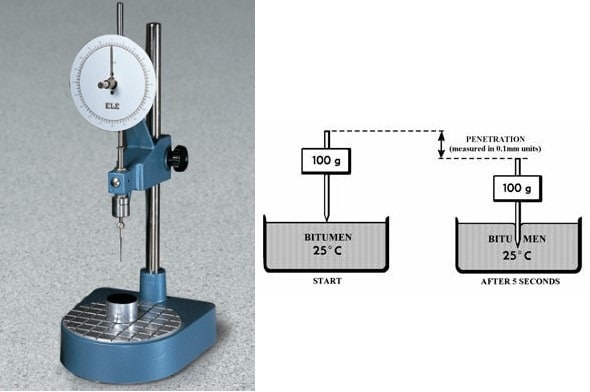

Penetration value is the vertical distance traversed or penetrated by the point of a standard needle into the bituminous material under specific conditions of load, time and temperature. This distance is measured in one tenths of a millimeter.

Penetration test is used for evaluating consistency of bitumen. It is not regarded as suitable for use in connection with the testing of road tar because of the high surface tension exhibited by these materials.

Penetration test on bitumen is carried to determine:

- Consistency of bituminous material

- Suitability of bitumen for use under different climatic conditions and various types of construction.

Table of Contents [show]

Determination of Penetration Value of Bitumen

Apparatus for Penetration Test

Container

A flat bottomed cylindrical metallic dish 55 mm in diameter and 35 mm in depth is required. If the penetration is of the order of 225 or more, dish of 70mm diameter and 45mm depth is required.

Needle

A straight, highly polished, cylindrical hard steel rod.

Water bath

Water bath maintained at 25° ± 0.1 °C, containing not less than 10 litres of water, the sample being immersed to a depth not less than 100mm from top and supported on perforated shelf not less than 50mm from bottom of the bath.

Transfer dish or tray

Should provide support to the container & should not rock it. It should be of such capacity as to completely immerse container during test.

Penetration apparatus

Should be such that it allows needle to penetrate without much friction& is accurately calibrated to give results in one tenth of a millimeter.

Thermometer

Range 0- 44 °C and in readable upto 0.20 C.

Time measuring device

With an accuracy of l second.

Procedure for Bitumen Penetration Test

(i) Preparation of test specimen: Soften the material to a pouring consistency at a temperature not more than 60°C for tars and 90°C for bitumen above the approximate softening point and stir it thoroughly until it is homogeneous and is free from air bubbles and water.

Pour the melt into the container to a depth at least 10mm in excess of the expected penetration. Protect the sample from dust and allow it to cool in an atmosphere at a temperature between 15° to 30° C for one hour. Then place it along with the transfer dish in the water bath at 25° ± 0.1 °C, unless otherwise stated.

(ii) Fill the transfer dish with water from the water bath to depth sufficient to cover the container completely, place the sample in it and put it upon the stand of the penetration apparatus.

(iii) Clean the needle with benzene, dry it and load with the weight. The total moving load required is 100 ± 0.25 gms, including the weight of the needle, carrier and super-imposed weights.

(iv) Adjust the needle to make contact with the surface of the sample. This may be done by placing the needlepoint in contact with its image reflected by the surface of the bituminous material.

(i) Make the pointer of the dial to read zero or note the initial dial reading.

(ii) Release the needle for exactly five seconds.

(vi) Adjust the penetration machine to measure the distance penetrated.

(vii)Make at least 3 readings at points on the surface of the sample not less than 10 mm apart and not less than l0mm from the side of the dish. After each test return the sample and transfer dish to the water bath and wash the needle clean with benzene and dry it.

In case of material of penetration greater than 225, three determinations on each of the two identical test specimens using a separate needle for each determination should be made, leaving the needle in the sample on completion of each determination to avoid disturbance of the specimen.

Precautions during Penetration Test

- There should be no movement of the container while needle penetrates into sample.

- The sample should be free from any extraneous matter.

- The needle should be cleaned with benzene and dried before penetration.

Observations for Penetration Test

Actual test temperature = °C

| Penetration dial reading | Test 1 | Test 2 | Test 3 |

| (a) Initial | |||

| (b) Final | |||

| Penetration Value |

Result of Test

Mean Penetration Value =

Recommended Penetration Value of Bitumen

Penetration test is a commonly adopted test on bitumen to grade the material in terms of its hardness. A 80/100 grade bitumen indicates that its penetration value lies between 80 & 100.

Grading of bitumen helps to assess its suitability in different climatic conditions and types of construction. For bituminous macadam and penetration macadam, IRC suggests bitumen grades 30/40, 60/70, 80/100.

In warmer regions, lower penetration grades are preferred to avoid softening whereas higher penetration grades like 180/200 are used in colder regions to prevent the occurrence of excessive brittleness. High penetration grade is used in spray application works.

Comments

Specific Gravity Test of Bitumen – Procedure & Result

Water Content Test of Bitumen | Procedure & Result

Flash and Fire Test of Bitumen -Procedure and Result

Penetration Test of Bitumen - Procedure & Result

Viscosity Test of Bitumen- Absolute, Kinematic, Industrial Viscosity

Float Test of Bitumen | Apparatus, Procedure & Result

Ductility Test of Bitumen | Apparatus, Procedure, Result