Types of Soil Compaction Equipments -Types of Rollers

There are different types of rollers and other soil compaction equipments available. Use of these compacting machines depends on soil types and moisture conditions.

Different Types of Soil Compaction Equipments:

The soil compaction equipments can be divided into two groups:

- Light soil compacting equipments

- Heavy soil compacting equipments

1. Light Soil Compacting Equipments:

These equipments are used for soil compacting of small areas only and where the compacting effort needed is less. Below are light equipments for soil compaction:

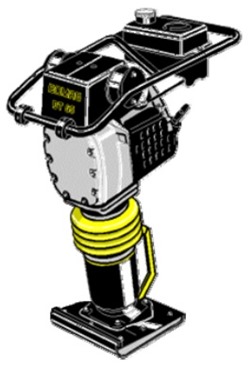

(i) Rammers:

Rammers are used for compacting small areas by providing impact load to the soil. This equipment is light and can be hand or machine operated. The base size of rammers can be 15cm x 15cm or 20cm x 20cm or more.

For machine operated rammers, the usual weight varies from 30kg to 10 tonnes (6 lbs to 22000 lbs). These hammers with 2- 3 tonnes (4400 to 6600 lbs)weights are allowed to free fall from a height of 1m to 2m (3ft to 7ft) on the soil for the compaction of rock fragments.

Rammers are suitable for compacting cohesive soils as well as other soils. This machine in areas with difficulty in access.

(ii) Vibrating Plate Compactors:

Vibrating plate compactors are used for compaction of coarse soils with 4 to 8% fines. These equipments are used for small areas. The usual weights of these machines vary from 100 kg to 2 tonne with plate areas between 0.16 m2 and 1.6 m2.

(iii) Vibro Tampers:

Vibro tampers is used for compaction of small areas in confined space. This machine is suitable for compaction of all types of soil by vibrations set up in a base plate through a spring activated by an engine driven reciprocating mechanism. They are usually manually guided and weigh between 50 and 100 kg (100 to 220 lbs).

2. Heavy Soil Compaction Equipments:

These compacting machines are used for large areas for use on different types of soils. The heavy compaction equipments are selected based on moisture content of soil and types of soil. Following are different types of these equipments:

I) Smooth Wheeled Rollers:

Smooth wheeled rollers are of two types:

- Static smooth wheeled rollers

- Vibrating smooth wheeled rollers

The most suitable soils for these roller type are well graded sand, gravel, crushed rock, asphalt etc. where crushing is required. These are used on soils which does not require great pressure for compaction. These rollers are generally used for finishing the upper surface of the soil. These roller are not used for compaction of uniform sands.

The performance of smooth wheeled rollers depend on load per cm width it transfers to the soil and diameter of the drum. The load per cm width is derived from the gross weight of the drum.

The smooth wheeled rollers consists of one large steel drum in front and two steel drums on the rear. The gross weight of these rollers is in the range of 8-10 tonnes (18000 to 22000 lbs). The other type of smooth wheel roller is called Tandem Roller, which weighs between 6-8 tonne (13000 to 18000 lbs).

The performance of these rollers can be increased by increasing the increasing the weight of the drum by ballasting the inside of drums with wet sand or water. Steel sections can also be used to increase the load of the drum by mounting on the steel frame attached with axle.

The desirable speed and number of passes for appropriate compaction of soil depends on the type of soil and varies from location to location. About 8 passes are adequate for compacting 20 cm layer. A speed of 3-6 kmph is considered appropriate for smooth wheel rollers.

Vibrating smooth wheeled rollers

In case of vibrating smooth wheeled rollers, the drums are made to vibrate by employing rotating or reciprocating mass.

These rollers are helpful from several considerations like:-

(i) Higher compaction level can be achieved with maximum work

(ii) Compaction can be done up to greater depths

(iii) Output is many times more than conventional rollers

Although these rollers are expensive but in the long term the cost becomes economical due to their higher outputs and improved performance. The latest work specifications for excavation recommends the use of vibratory rollers due to their advantage over static smooth wheeled rollers.

(ii) Sheepsfoot roller Roller:

Sheepsfoot rollers are used for compacting fine grained soils such as heavy clays and silty clays. Sheepsfoot rollers are used for compaction of soils in dams, embankments, subgrade layers in pavements and rail road construction projects.

Sheepsfoot rollers are of static and vibratory types. Vibratory types rollers are used for compaction of all fine grained soils and also soil with sand-gravel mixes. Generally this roller is used for compaction of subgrade layers in road and rail projects.

As seen in picture above, sheepsfoot rollers consist of steel drums on which projecting lugs are fixed and can apply a pressure upto 14kg/sq cm or more. Different types of lugs are namely spindle shaped with widened base, prismatic and clubfoot type.

The weight of drums can be increased as in the case of smooth wheeled rollers by ballasting with water, wet sand or by mounting steel sections.

The efficiency of sheepsfoot rollers compaction can be achieved when lugs are gradual walkout of the roller lugs with successive coverage. The efficiency is affected by the pressure on the foot and coverage of ground obtained per pass. For required pressure and coverage of ground, the parameters such as gross weight of the roller, the area of each foot, the number of lugs in contact with the ground at any time and total number of feet per drum are considered.

The compaction of soil is mainly due to foots penetrating and exerting pressure on the soil. The pressure is maximum when a foot is vertical.

(iii) Pneumatic Tyred Rollers:

Pneumatic tyred rollers are also called as rubber tyred rollers. These rollers are used for compaction of coarse grained soils with some fines. These rollers are least suitable for uniform coarse soils and rocks. Generally pneumatic tyred rollers are used in pavement subgrade works both earthwork and bituminous works.

Pneumatic rollers have wheels on both axles. These wheels are staggered for compaction of soil layers with uniform pressure throughout the width of the roller.

The factors which affects the degree of compaction are tyre inflation pressure and the area of the contact. The latest rollers have an arrangement to inflate the tyre to the desired pressure automatically. The total weight of the roller can be increased from 11.0 tonne to 25.0 tonne or more by ballasting with steel sections or other means.

(iv) Grid Rollers:

Grid rollers are used for compaction of weathered rocks, well graded coarse soils. These rollers are not suitable for clayey soils, silty clays and uniform soils. The main use of these rollers are in subgrade and sub-base in road constructions.

As the name suggests, these rollers have a cylindrical heavy steel surface consisting of a network of steel bars forming a grid with squire holes. The weight of this roller can be increased by ballasting with concrete blocks.

Typical weights vary between 5.5 tonnes net and 15 tonnes ballasted. Grid rollers provide high contact pressure but little kneading action and are suitable for compacting most coarse grained soils.

(v) Pad Foot / Tamping Rollers:

These rollers are similar to sheepsfoot rollers with lugs of larger area than sheepsfoot rollers.

The static pad foot rollers also called tamping rollers have static weights in the range of 15 to 40 tonnes and their static linear drum loads are between 30 and 80 kg/cm. These rollers are more preferable than sheepsfoot roller due to their high production capacity, and they are replacing sheepsfoot rollers.

The degree of compaction achieved is more than sheepsfoot rollers. The density of soil achieved after compaction with this roller is more uniform.

These rollers operate at high speeds, and are capable to breaking large lumps. These rollers also consists of leveling blades to spread the material.

Pad foot or tamping rollers are best suitable for compacting cohesive soils.

Comments