Movable Excavation Supports for Trench and Foundation Construction

The use of movable excavation supports for trench and foundation construction is widely popular for providing adequate support. It is a must in every engineering project in which ground works are involved.

Movable supports provide several advantages such as quick installation and removal, offer safe working place for labors and sufficiently restrict ground movements.

In this article, types of movable supports and selection criteria will be discussed.

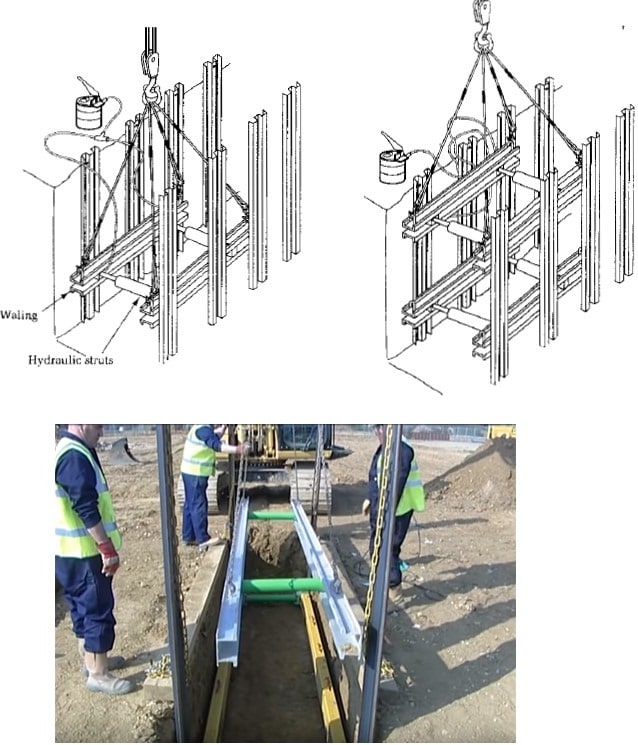

Fig.1: Movable Excavation Supports for Trench and Foundations (Used for Heavy Construction)

Fig.2: Movable Excavation Support for Trench

Movable Excavation Supports for Trench and Foundation Construction

- Selection of Movable supports for Excavations

- Major types of movable supports for excavation

Selection of Movable supports for Excavations

Following are the factors considered while selecting suitable movable supports for excavations:

- The nature of the soil at project site.

- The required size of the excavation area.

- The depth and flow of ground water if it is present in the area.

- The size of the structure planned to be built in the excavated area

Major Types of Movable Supports for Excavation

Major types of movable supports for excavation are:

- Hydraulic frames or waling frames

- Shores

- Boxes

- Sliding panels

- Shields or drag box

Hydraulic Frames or Waling Frame Supports for Excavations

It is an adaptable type of excavation support system and provides considerable positive to the surrounding ground. It can be used for average size trenches (maximum 4m wide and 6m deep) disregard of soil condition, specifically appropriate to be used in cities and towns.

Hydraulic frames consist of waler frame (steel or aluminum rails), hydraulic rams, and sometimes steel trench sheets. Experienced engineer is required for use of waler frames if the depth of excavation exceeds 3.5m, ground condition is poor, or the surcharge loads are large.

Fig.3: Hydraulic Waler Frame Movable excavation Support

As far as installation procedure is concerned, Figure 4 to Figure 6 illustrate steps for waler frame placement.

Fig.4: Trench sheets or runners are force into the ground below the bottom of the trench to temporarily support themselves

Fig.5: Install roller frames which consist of two fixed length aluminum or steel and held together by hydraulic rams

Fig.6: Install the Remaining Steel Trench Sheets

Shores Movable Supports for Excavations

Shores are composed of a pair of steel sheet held together by hydraulic rams as shown in Figure-7. They are assembled outside the excavation, so soil should be fairly stable and must be non-bearing water ground condition.

The size of excavation is maximum 2m wide and 2m depth and the spacing between vertical shores is commonly 1.2m. Shores just provides temporary support for excavated area.

Fig.7: Installed Shores

Box Movable Supports for Excavations

Boxes are the first option to be considered to support excavations in rural areas. Various box sizes are manufactured and available to be used.

The boxes are assembled on the ground and then lowered to into the trench. If the depth of excavation is high, then it is possible to install two boxes on each other.

It is suitable for a trench with maximum width of 4m and depth of 6m. It cannot be used for saturated soil condition. Special box sizes are also available for manhole construction.

Fig.8: Box Movable Excavations Support

Sliding Panel Movable Excavation Support

This type of movable excavation support can be used in nearly all soil conditions and can support 7m depth and 7m wide trenches. It is suitable for the case where positive ground support condition is required.

Components of sliding panels are posts, sliding panels and struts. The installation procedure includes driven steel rails into either partially excavated trench or forced into the ground from ground surface if the soil is not stiff.

Then, slide panels are placed between steel rails, after that both steel rails and sliding panels are pushed into the ground as the excavation is progressed.

Fig.9: Sliding Panels Movable Excavation Support

Shields or Drag Box Movable Excavation Support

As it can be observed from the name, the major purpose of using shields or drag boxes is to create a safe working place for labors. Drag box is composed of two panels which are welded together.

It is lowered into excavation area using suitable machines and pulled along the trench the work is progressed. The condition of the soil at the project site should be stable and maximum size of the trench is 4m wide and 4 deep for single drag box unit.

The length of each unit is about 7m and greater length would be impractical because the weight would be considerably great.

This type of movable support as shown in Figure 10 is a good option for rural areas, not appropriate for urban area.

Fig.10: Drag Box Type Movable Support

References:

CPA. Selection of Proprietary Shoring Equipment. Shoring Technology Interest Group (STIG). London, p. 2-8. 2002..

Kamran M. Nemati. Temporary structure: Excavation and excavation supports. The University of Washington. Washington, p. 4-6. 2007. (CM 420).

MJ Tomlinson. Foundation Design and Construction. 6th edition. ed. Edinburgh: Pearson Education Limited, 1999.

Comments